Bright Designs Fast: Shirt Heat Press of Sublimation Paper T-Shirts can be defined as the process of transforming blank shirts into full-color items of bright shades with the use of sublimation paper and a quality heat press. The method will guarantee crisp, durable designs.

Prefer beautiful t-shirts, whop girls? A heat press boiled with sublimation paper makes your ideas come out in vivid colors and is very professional.

Heat pressing ensures that the temperature and pressure are the same; hence, sublimation inks are transferred impeccably. What has been achieved is the product of bright, long-lasting shirts that are unique and can repel time and multitudinous washings.

What’s the explanation of sublimation shirts being done using a heat press?

A shirt heat press offers even heat and pressure, which is crucial to sublimation transfers. A heat press does not afford any uneven spots, fading, or misaligned prints like irons or other manual techniques do.

Adjustments to various shirt fabrics are made through the use of digital temperature and timer controls. This will guarantee that sublimation inks sink into the fibers flawlessly, producing permanent designs in vibrant colors.

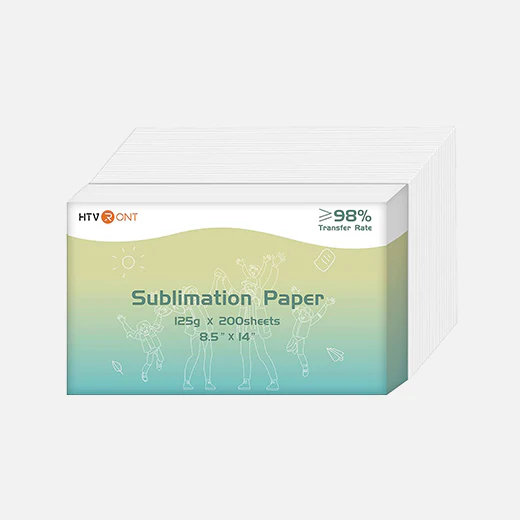

The Power of Sublimation Paper.

Sublimation paper is a sublimation inking material that contains sublimation inks until heat is applied to initiate the transfer process. The essay is converted into a gas when heated. Imprints itself into the shirt filaments, producing rich, full-color patterns that won’t crack or peel.

Good quality sublimation paper would have sharp graphics and colors that are consistent. The poor quality of paper may lead to dull colors, blurred images, or uneven prints that lower the professional appearance in general.

To make shirts to be sublimated.

The most important thing in perfect transfers is preparation. Warm the shirts in the dryer to take out the moisture and wrinkles and allow the transfer to be smooth.

The second thing to do is to make sure that your design fits perfectly on the shirt and place it with heat-resistant tape. The correct preparation will ensure that there is no shifting, blurring, or misprints in the pressing process.

This is always done on scrap material so that you can ensure that the color and heat settings are correct before the actual shirt is pressed.

Procedures of the Ideal Sublimation Transfers:

- Warm the shirt to dry and eliminate wrinkles.

- Print your design on sublimation paper using compatible inks.

- Underline the design on the shirt and use taping.

- Adjust the heat press and set it to the suggested time and temperature.

- Put pressure and ensure that it is not too strong and the shirt is kept cool and the paper is removed.

Choosing the Right Fabric for Your Sublimation Printing.

Polyester shirts and polyester blend shirts are preferred for printing through sublimation. These materials take up the sublimation ink in an appropriate manner, and this gives a bright and permanent print.

Other fabrics that should not be used are cotton fabrics because sublimation inks do not adhere to natural fabrics. Mixed fibers (polyester at least 50-65) could be used but would yield rather dull colors.

Pressing Points to Unified Quality.

Proper heat, pressure, and timing are of great essence. The best transfer time, a time of 30-60 seconds at 375-400°F (190-204°C), is achieved on most polyester shirts based on the thickness of the garment and brand name.

Even pressure is used to make the entire design stick together. You can change your settings according to your fabric, ink, and sublimation paper requirements to prevent such an outcome as fading or misaligned transfers.

Ideas to be developed in sublimation shirts.

The sublimation printing is limited by no creativity. You may print vivid logos, full-color images, personal designs, or even elaborate art.

Heat transfer vinyl (HTV) can be applied to sublimation prints with the purpose of creating raised textures and contrast to create unique and multi-dimensional designs. This mix is best suited to customize gifts, fashion clothing, or to promote products.

Recurring tools and accessories that facilitate printing.

- Digital temperature and timer control shirt heat press that is reliable.

- Sublimation paper and inks of good quality.

- Tape to be used during placement: heat-resistant.

- Teflon sheets to keep off scorching.

- Before pressing lint rollers to remove dust.

When using your heat press platen, make sure it is always clean to avoid the leftovers being transferred to other new shirts.

The correct tools minimize crimes and time destruction and also maintain an invariant high-quality affair at all times.

Common miscalculations to Avoid

Excessive or inappropriate time and/or pressure may cause colored or burnt-out designs. The manufacturer of sublimation paper and ink should always be observed.

Any slippage or misalignment of the sublimation paper will spoil a shirt. The design is secured using tape, and a smooth surface is maintained so as to avoid such problems.

People should not skip the preheating of the shirt, as any moisture that will interfere will be present. The process of pre-press is a simple step that produces vibrant, flawless designs.

Sublimation Shirts Dressing.

Sublimation designs are various and must be taken good care of to maintain their color and permanence. Wash the shirts in cold water and in low-attention soap.

Don’t drop hard or dry using a lot of heat, and this will make the colors fade down. It is air-dried or dried in low heat to preserve the look and durability of the shirt.

The benefits of a Shirts Heat Press.

- Guarantees smooth heat and pressure of perfect sublimation transfers.

- Gives vivid and long-lastingshirt heat presses. colors.

- Efficiently works on both large and small-scale production runs.

- Accepts multi-layered designs in all colors and creative designs.

- Saves time and eliminates mistakes as opposed to manual pressing.

A shirt heat press makes the task a lot easier, as it provides professional outcomes at all times and in the most efficient way.

Conclusion

Bright Designs Fast: Shirt Heat Press on Sublimation Paper T-Shirts converts plain shirts to high-quality and colorful professional shirts. The transfers, colors, and durability of the results can be achieved with the help of a heat press and sublimation paper.

It requires the appropriate materials, a well-thought-out preparation, and the correct technique so that any person can produce the t-shirts that are eye-catching, personal, a gift, or even a business. The printing process for custom shirts uses a technique that enables quick and accurate printing of unique designs.

FAQs:

1. Is it possible to sublimate print on cotton shirts?

The process of sublimation achieves its loftiest effectiveness when applied to polyester and polyester-mix fabrics because cotton accoutrements don’t produce a strong bond with sublimation inks.

2. How long does it take to complete the sublimation process on a shirt?

The endless sublimation prints maintain their vibrant colors through proper use because they don’t witness cracking or shelling.

3. Will it be possible to use sublimation and HTV on the same shirt?

The application of HTV on top of sublimation prints creates a textured surface, which produces a multi-dimensional design through its different visual elements.